Wheelchair Preparation: Difference between revisions

No edit summary |

No edit summary |

||

| Line 187: | Line 187: | ||

Helps to hold the pelvis upright at the back of the cushion. | Helps to hold the pelvis upright at the back of the cushion. | ||

* '''Slung seat base''' | * '''Slung seat base''' | ||

Cushions used on a slung wheelchair seat have a bevel cut on each side of the base of the cushion.This allows the cushion to take up the shape of the slung wheelchair seat. The top of the cushion then stays flat. | Cushions used on a slung wheelchair seat have a bevel cut on each side of the base of the cushion.This allows the cushion to take up the shape of the slung wheelchair seat. The top of the cushion then stays flat. | ||

'''A top layer, made with a soft “comfort” foam''': | '''A top layer, made with a soft “comfort” foam''': | ||

Revision as of 06:45, 22 May 2018

Original Editor - Your name will be added here if you created the original content for this page.

Top Contributors - Vidya Acharya, Naomi O'Reilly, Laura Ritchie, Kim Jackson, Amrita Patro and Jess Bell

Introduction[edit | edit source]

The wheelchair service provision process is not simply assessment followed by prescription; but providing a client with an appropriate wheelchair. Wheelchair preparation is the Step number five in Wheelchair service delivery, as per the eight steps of wheelchair service delivery, described in the WHO guidelines on the provision of manual wheelchairs in less resourced settings.

The objective of good practice in product preparation is to prepare the wheelchair for the fitting, including modifications or custom postural support component[1].

Once the equipment is received, the wheelchair base/frame, options, accessories, and seating and positioning components should be assembled and set-up according to the preliminary specifications detailed in the recommendation and selection process. This includes fabrication and installation of custom items and assessment of the function and operation of all mechanical components.

During this step, the wheelchair and its accessories and the seating and positioning components will be set up in accordance with the recommended specifications, based on the assessment and trial of equipment.

Wheelchair preparation includes:[2][edit | edit source]

• preparing the wheelchair to match the wheelchair user’s prescription (selection);

• checking the wheelchair to make sure that it is safe and ready to be used and all parts are working properly.

Good practice in product preparation[1]:[edit | edit source]

- Each wheelchair being prepared is labeled with the user’s name and a serial number or bar code.

- Modifications to wheelchairs (permanently altering the frame or a component of the wheelchair) are carried out only by personnel with the appropriate knowledge and skills, since any such modification may have structural and functional implications.

- The production and installation of custom seating systems or individual postural support components should be carried out by personnel with the appropriate knowledge and skills. This work should also be done in close collaboration with the assessment personnel.

- All mobility equipments should be checked for quality and safety before the user tries it.

Steps in preparing the wheelchair:[edit | edit source]

Prepare the wheelchair in the following order:

1. Check that the wheelchair seat width and depth measurements are correct for the prescription (selection).

2. Check that the cushion width and depth match the seat.

3. Adjust (where possible):

• Backrest height and angle;

• Armrests height;

• Rear wheels position;

• Brakes position;

• Footrests height;

• Push handles height;

• Any other adjustments.

4. Carry out a “wheelchair safe and ready” check.

Wheelchair safe and ready checklist:[edit | edit source]

Use the checklist below to make sure that the wheelchair is safe to use and all parts are working. Always do this before the wheelchair user tries the wheelchair

Checklist: Is the wheelchair safe and ready to use? [2]| For the whole wheelchair | How to check | |

| There are no sharp edges | Check all over the wheelchair with eyes and hands | |

| No parts are damaged or scratched. | ||

| The wheelchair travels in a straight line | Push the wheelchair away from you, making sure the castor wheels are in the “trail” position. | |

| Front castor wheels | ||

| Spin freely. | Tip the wheelchair on to the back wheels. Spin the castor wheels. | |

| Spin without touching the fork. | ||

| Bolts are tight. | Check. They should feel firm. Do not over tighten. | |

| Front castor barrels | ||

| Castor fork spins freely. | Tip the wheelchair on to the back wheels. Spin the castor fork around. | |

| Rear wheels | ||

| Spin freely. | Tip the wheelchair sideways on to one rear wheel. Spin the other wheel. Check the other side. | |

| Axle bolts are tight. | Check. They should feel firm. Do not over tighten. | |

| Tyres (if those are pneumatic) are inflated correctly. | Press on the tyres with your thumb. The wheel should depress a little, but no more than 5 mm. | |

| Push rims are secure | Check | |

| Brakes | ||

| Function properly | Apply brakes. Check the wheelchair cannot be moved. | |

| Footrests | ||

| Footrests are securely attached. | Check. | |

| Frame | ||

| Cross-folding wheelchair folds and unfolds easily. | Fold the wheelchair to check that the folding mechanisms are working correctly. | |

| Fold-down backrest – the backrest folds and unfolds easily. | ||

| Cushion | ||

| The cushion is in the cover correctly. | Usually the cushion cover is done up at the back of the cushion, underneath. | |

| The cushion is sitting on the wheelchair correctly. | If the cushion is contoured, the “well” for the seat bones should be at the back of the seat. | |

| The cushion cover fabric is tight but not too tight. | The cushion cover should not stretch tightly over any contours of the cushion. | |

| The cushion fully covers the seat | Check that no part of the seat is visible from under the cushion. This is particularly important for solid seats. | |

Cushion fabrication[edit | edit source]

- If foam is available, wheelchair service personnel can make a foam pressure relief cushion with just a few tools. Personnel need to know what foam to use, and a few important dimensions.

- Discuss with the trainers the availability of foam and type of foam suitable for a pressure relief cushion.

- The instructions below show how to make a basic foam pressure relief cushion, with two key contours. These are a “well” under the seat bones and a shelf in front of the seat bones.

Cushion features and dimensions: The main features of the basic foam contoured cushion are the following:-

A base layer, made with a firm foam (for example “chip” foam):

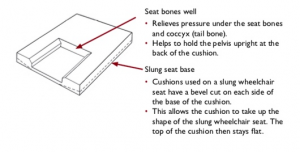

- Seat bones well

Relieves pressure under the seat bones and coccyx (tail bone).

Helps to hold the pelvis upright at the back of the cushion.

- Slung seat base

Cushions used on a slung wheelchair seat have a bevel cut on each side of the base of the cushion.This allows the cushion to take up the shape of the slung wheelchair seat. The top of the cushion then stays flat.

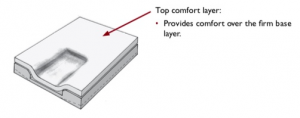

A top layer, made with a soft “comfort” foam:

Top comfort layer: Provides comfort over the firm base layer.

How to make a pressure relief cushion base?[edit | edit source]

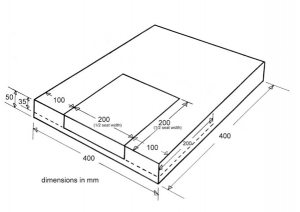

The following instructions provide a cushion of dimensions 400 mm wide x 400 mm deep x 50 mm high. The seat bones well is 200 mm wide x 200 mm deep x 35 mm high. This cushion would be suitable for a wheelchair user with a seat width of 400 mm. Adapt the dimensions to suit the size of each wheelchair user as described in the box below.1. Mark out the cut lines on the firm foam.• Start with a piece of firm foam 400 mm x 400 mm x 50 mm.

•The centre of the seat bones well must be on the centre line of the cushion.

•For this size cushion, the seat bones well should measure 200 mm x 200 mm x 35 mm.

•Draw the cut lines with a dark coloured marker on all six sides of the base foam.References[edit | edit source]

- ↑ 1.0 1.1 Guidelines on the provision of Manual Wheelchairs in less resourced settings,3.Service delivery ,Page No. 82:Product preparationhttp://www.who.int/disabilities/publications/technology/English%20Wheelchair%20Guidelines%20(EN%20for%20the%20web).pdf

- ↑ 2.0 2.1 World Health Organisation; Wheelchairervicetraining package; Reference Manual For Participants; Basic Level; Step 5 Product Wheelchair preparation; Page No.55,56http://apps.who.int/iris/bitstream/handle/10665/78236/9789241503471_reference_manual_eng.pdf?sequence=1 .